| |

| Standard

Conduit |

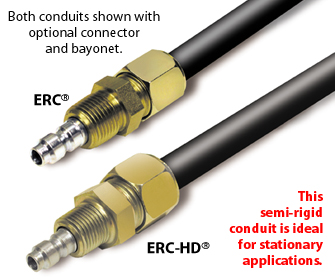

| ERC®

& ERC-HD® |

|

|

| ERC®

& ERC-HD® CONDUIT:

Electron Beam’s ERC® (Extended Reach Conduit)

and ERC-HD® (Heavy-Duty) Conduits are both designed

for extended run lengths. They resist wear and reduce

feed pressure due to their limited bending. Ideal for

stationary applications, they will not stretch or compress,

and are electrically insulated. |

|

| CAPABILITIES/SPECIFICATIONS:

With an abrasive saw, the conduit may be cut to any

length desired and field terminated with the respective

ERC® or ERC-HD® Connector. |

|

ERC® Conduit:

ERC® Conduit:

Recommended for delivery

of solid welding electrodes up to 3/32” (2.4mm)

diameter or cored wires up to 5/64” (2.0mm). To

maintain quality performance, it is not recommended

to bend ERC® Conduit to less than a 12” (30.5cm)

radius. Flexing of the conduit should be limited. |

| |

ERC-HD® Conduit:

ERC-HD® Conduit:

Recommended for delivery

of solid welding electrodes up to 1/8” (3.2mm)

diameter, or cored wires up to 7/64” (2.8mm).

To maintain quality performance, it is not recommended

to bend ERC-HD® Conduit to less than a 18”

(45.7cm) radius. |

|

|

| ERC®

& ERC-HD® CONNECTORS |

| |

|

|

| |

| ERC-HD®

Connector |

|

|

ERC®

and ERC-HD® Connectors:

To be used with their respective conduit. Consists

of a reusable Compression Nut, hardened Ferrule, and

Connector Body. To install, slip the assembly fully

over the conduit and tighten the compression nut to

retain the connector to the conduit. These connections

terminate in a male 1/2” NPT pipe thread, popular

with many pay-off arms. Add the ERC® Bayonet to

the assembly to convert the connector to a “quick

connect”. |

|

|

| |

| ERC®

Bayonet |

|

|

| ERC®

Bayonet:

Use

with the ERC®

Connector or ERC-HD®

Connector to provide a quick connection to all Adaptor

Kits and Connectors. To install, simply slide the bayonet

into the connector prior to installing the connector

onto the conduit.

|

|

|

DESCRIPTION |

|

REF.

NO. |

|

|

MATES

TO:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

All

Conduits |

|

|

|

|

All

Conduits |

|

|

|

|

|

|

| To

Top |

|

|

|

|

| |

| |

| FLAT

WIRE MONOCOIL CORE:

The flat wire monocoil core is precision wound from

long-lasting, high carbon, hardened steel spring wire

for a longer, productive life. Manufactured to larger

I.D. clearances which is especially useful in reducing

wire drag. |

|

POLYETHYLENE

INSULATING JACKET:

The thick wall extruded polyethylene jacket reinforces

the wire monocoil while limiting bending and resisting

“snaking” conditions caused by electrode

cast. Superior wire transfer is accomplished due to

this reinforcement over long distances with minimal

bends. |

|

.312”

(7.9mm) I.D. |

.625”

(15.9mm) O.D. |

|

.357”

(9.0mm) I.D. |

.750”

(19.1mm) O.D. |

|

|

|

|

| A-2048 |

ERC

100’ (30.48m) |

| ERC

250’ (76.20m) |

|

| A-2049 |

ERC-HD

100’ (30.48m) |

|

|

Note:

Cut lengths available by special order.

|

|

|

|